The Ins and Outs of the IoT for Transportation and Logistics

December 13, 2022

While optimizing fleet management, routes, asset tracking, and driver engagement, the Internet of Things requires security, connectivity, budgets, and expertise.

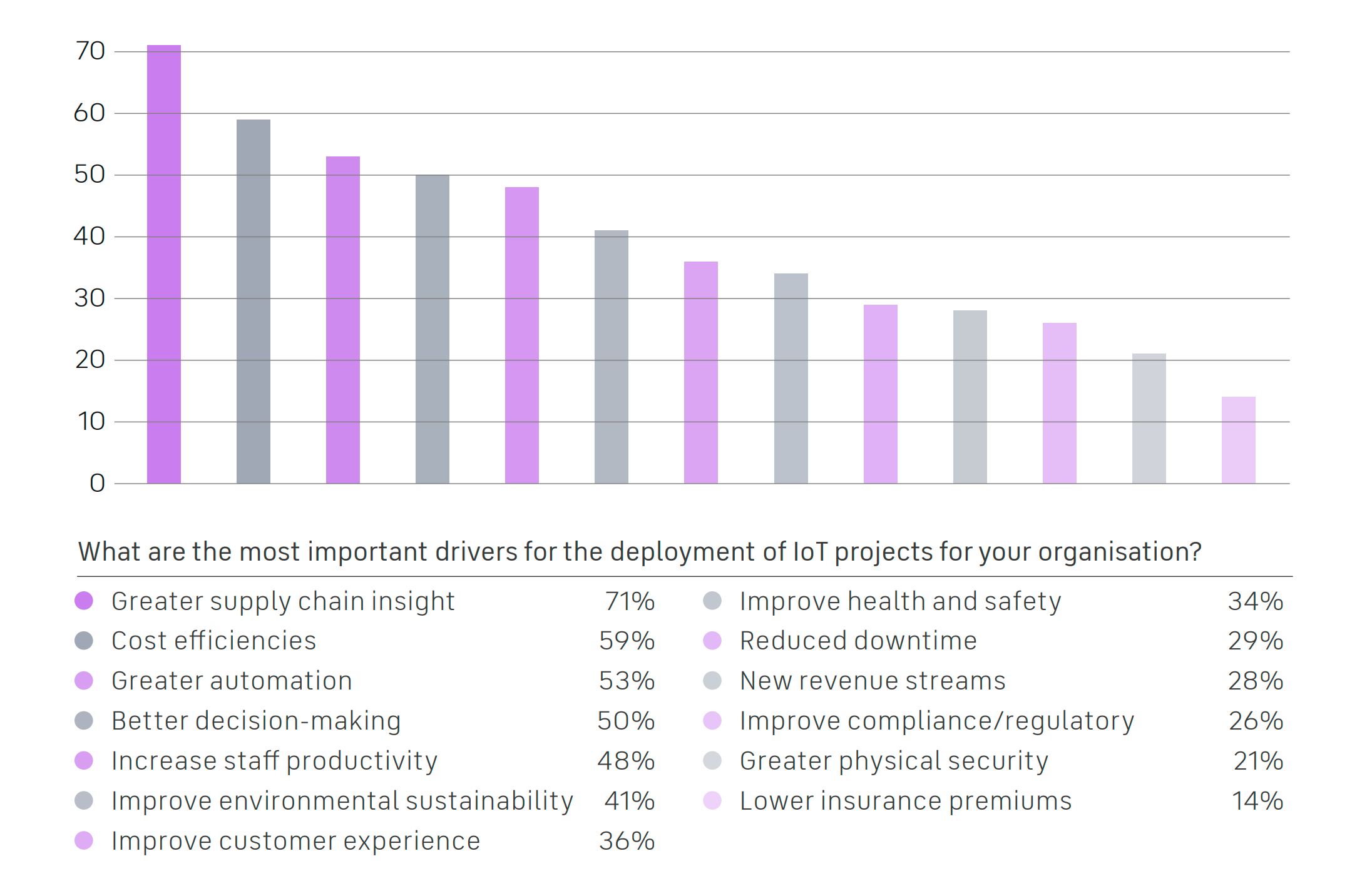

The state of the IoT in transportation

Today, transportation and logistics are making the world interconnected and “smaller.” Over the last two decades, the Internet of Things (IoT) has further amplified this effect, providing the industry with networks of devices to meet both operational and analytical requirements. These include accurate insights into the supply chain, automation, cost efficiency, and enhanced decision-making, according to a 2021 report by Inmarsat, a global satellite communications provider. Besides, 54% of respondents considered the IoT important to address the supply chain issues that arose during the COVID-19 pandemic.

These advantages are likely to further catalyze the adoption of the IoT in the transportation industry in the near future. Ericsson expects the number of cellular IoT connections in transportation to grow from 100 million in 2020 to 292 million in 2030.

Adoption drivers for implementing the IoT (source: Inmarsat)

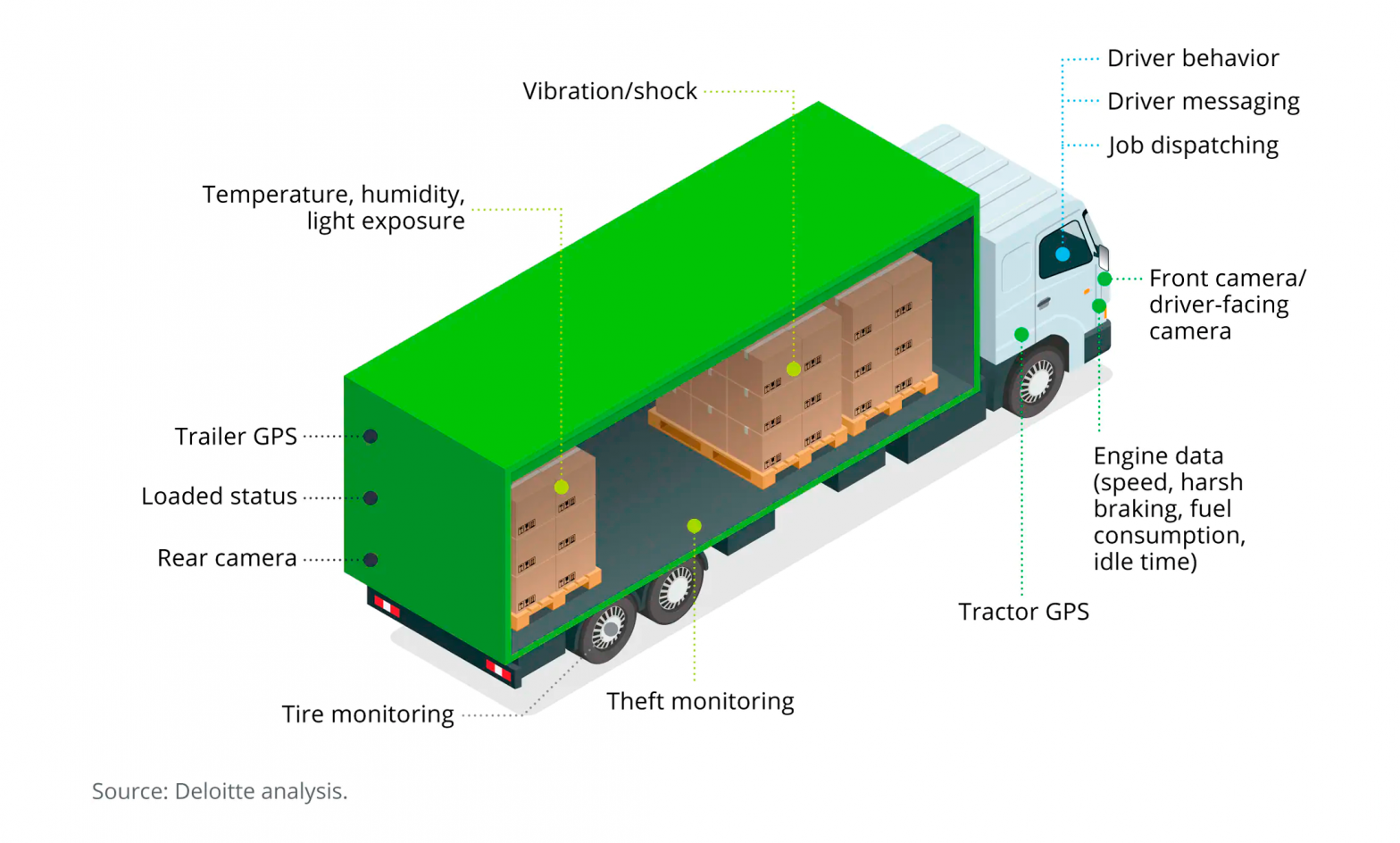

Adoption drivers for implementing the IoT (source: Inmarsat)The Internet of Things in transportation relies on sensors that collect data from moving assets, be it vehicles or goods, and from related infrastructures (such as terminals and warehouses). This information is then processed by data analytics solutions and used to harmonize the supply chain (route optimization, load capacity, maintenance, driver safety, etc.).

Despite the advantages of IoT in logistics and supply chain, several companies get stuck in what McKinsey defines as a “pilot purgatory.” This article sheds some light on the barriers that occur during IoT adoption in transportation and explains why companies still invest in innovations like this despite the obstacles.

Common scenarios

McKinsey, Deloitte, and Verizon observe the following most common scenarios for adopting the IoT in transportation.

1. Fleet management

Coordinating vast fleets of vehicles requires huge organizational efforts. IoT systems help to streamline such workflows in several ways. Transportation providers can supervise demand and fleet availability to optimize vehicle allocation. They can also adapt routes based on location, traffic, weather, or road conditions, as well as send updates (including estimated arrival time) to drivers and partners via integrated communication systems.

For example, DHL implemented an IoT-based fleet management system named SmarTrucking to improve fleet scheduling and shipment visibility. According to the company, the solution may reduce transit times by up to 50%.

2. Tracking assets and goods

This use case of the IoT in logistics can involve both vehicles and the goods they transport, such as pallets and parcels. Asset tracking represents a key element to efficient management of the supply chain and workflows in warehouses, yards, and terminals. This includes operations such as outbound order shipping, loading in docking stations, truck queuing at ports, etc.

In this regard, Airbus implemented a GPS-based IoT system to track 15,000 connected packages, minimize asset misplacements, and send timely notifications in case of deviations. Another example would be a Norwegian software provider for transportation that partnered with us to automate order planning. The developed platform enabled each of 100+ logistics companies using it to facilitate the delivery of 1,000 orders on a daily basis.

3. Condition monitoring and maintenance

Combining IoT sensors and ML-based software, it is possible to collect vehicle health data, such as fuel consumption, tire pressure, and engine performance. This data is analyzed via ML algorithms to identify any deviations from standard conditions and predict future failures. Once the system detects an anomaly, it can send an alert and request maintenance.

A mining corporation Rio Tinto, for example, adopted a pilot IoT platform based on Azure to monitor trucks and other equipment. The initiative facilitated asset maintenance and streamlined the supply chain.

4. Driving optimization

An IoT platform can keep track of shifts and resting times to facilitate compliance with labor regulations. It is also possible to monitor and analyze driving behavior to offer insights that will help improve safety while reducing fuel consumption.

A similar solution for truck driver assistance and trailer monitoring has been developed by ZF Group, a German manufacturer of automotive components. The software aims at promoting safer and eco-friendly driving behavior, as well as cutting 6% of expenses by a mid-size truck transport company.

One step forward toward the future of the IoT in logistics will be a large-scale adoption of autonomous vehicles, where drivers would have a merely supervisory role. However, similar solutions are still not in commercial use, as highlighted by McKinsey.

5. Cold-chain delivery

Transporting temperature-sensitive products, such as medicine, vaccines, or food, can be particularly complex both in operational and regulatory terms. Cold-chain delivery is aimed at addressing this challenge, and the Internet of Things in transportation can be one of its most valuable tools. Sensors are commonly used to analyze and ensure optimal cargo conditions, therefore, maintaining product quality and minimizing losses.

For instance, an air cargo carrier partnered with us to develop an IoT system that can monitor temperature and humidity at up to 10,000 aircrafts, transporting pharmaceuticals. The testbed for the project comprised 3,000 sensors with a possibility to scale on demand.

What are the technical challenges?

Issue #1. Integration

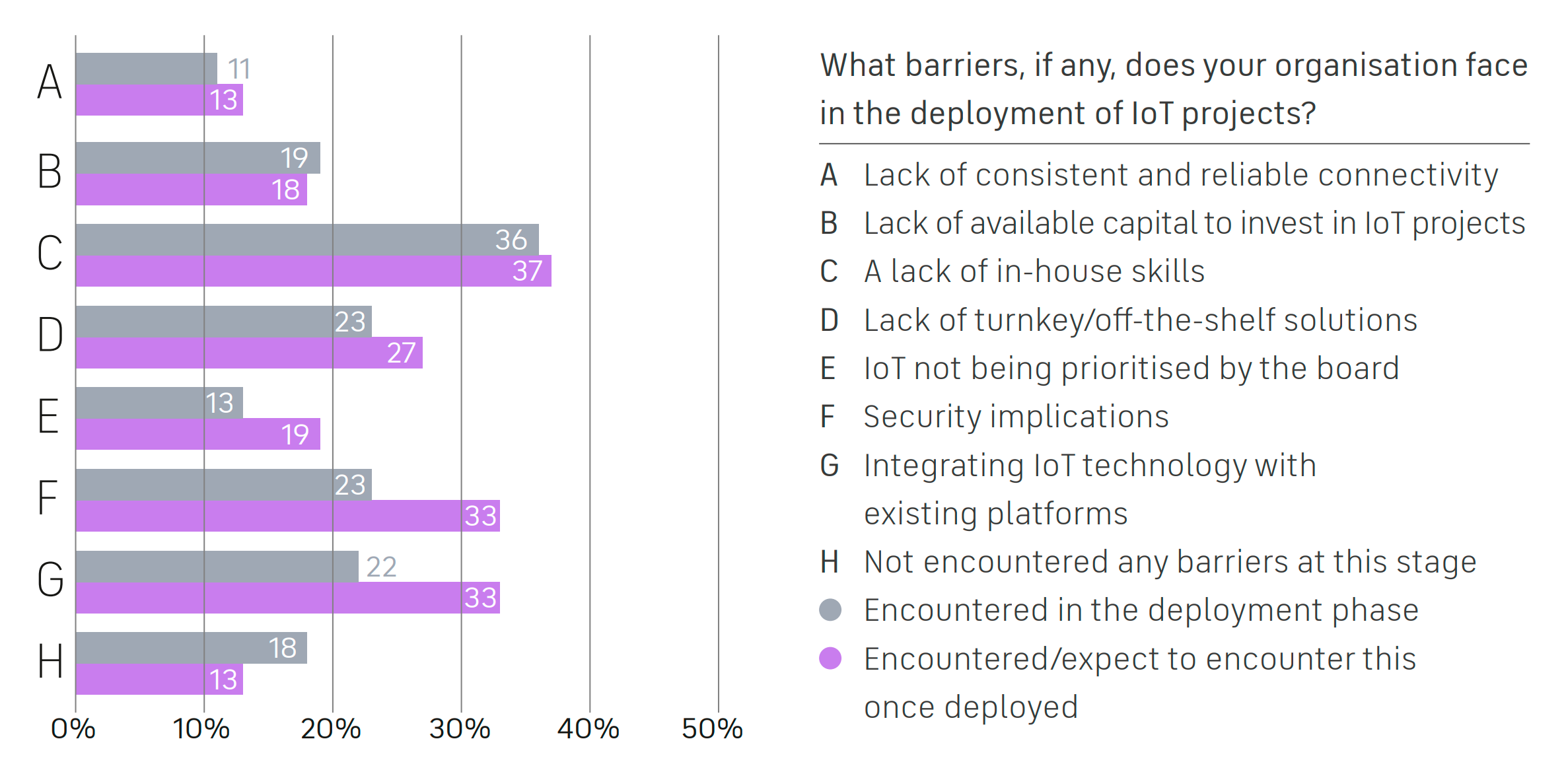

Integrating multiple components that comprise an IoT system can be rather complex. In logistics, IoT systems rely on thousands of sensors mounted on transportation means and assets to gather all sorts of data: location, speed, temperature, humidity, etc. To deliver meaningful insights and analytics, all this data has to be gathered and processed in real time. The report by Inmarsat reveals that integration in one of the top challenges for organizations during both deployment phase and once deployed.

IoT adoption barriers in transportation and logistics (source: Inmarsat)

IoT adoption barriers in transportation and logistics (source: Inmarsat)The thing is that sensors may come from different manufacturers and employ different networking protocols under the hood. So, in addition to integrating sheer volumes of real-time data, there is an issue with the compatibility of underlying protocols and data formats they use. The need to store this data for analysis and reporting, as well as synchronize it with corporate systems only amplifies the problem.

For instance, one of our customers needed to gather data from 5,300 devices in real time—for its fleet management platform.

When it comes to big data in the IoT, Amazon suggests pairing traditional relational databases with NoSQL solutions. The latter store data distributedly as objects (documents or a key-value pair), which promotes performance, consistency, and flexibility. There are numerous options out there, including Couchbase Server, MongoDB, Cassandra, etc.

At the architecture level, serverless solutions bring quite a few perks to the table. In essence, the concept implies that all the trouble around allocating and managing computing resources is on the cloud provider’s side. According to DataStax, a serveless approach and IoT systems are a perfect match if your priorities are performance under high loads, availability during spikes, and scalability.

Moving onto the protocol compatibility, it’s worth considering the implementation of an enterprise service bus (ESB). There also exist specific tools to tackle the issue of heterogeneous protocols and data—e.g., AWS IoT Greengrass.

Issue #2. Connectivity

While the IoT in manufacturing typically deals with stationary assets, the same can’t be said about transportation and logistics. This means that a truck may enter cellular network blind spots, such as tunnels or rural areas, resulting in high latency or lost connection between sensors and an IoT platform.

To address this disadvantage, HiveMQ recommends relying on a publish–subscribe pattern with IoT sensors loosely coupled to other platform components. When a connection is available, IoT devices deliver and receive data in real time. Otherwise, these devices memorize historical data with time stamps assigned to it and create an offline message queue. As soon as the connection is restored, all buffered information will be sent to the cloud, preventing any loss of messages. Such data points with associated time stamps are typically stored in time-series databases, as they’re optimized to handle this type of information.

When it comes to latency in transportation scenarios, another solution suggested by McKinsey is edge computing. The idea is to move part of the storage and computing resources from traditional data centers to the devices, where data is actually generated (vehicles or terminals). This minimizes the distance between data sources (IoT devices) and the processing power, reducing dependency on the network.

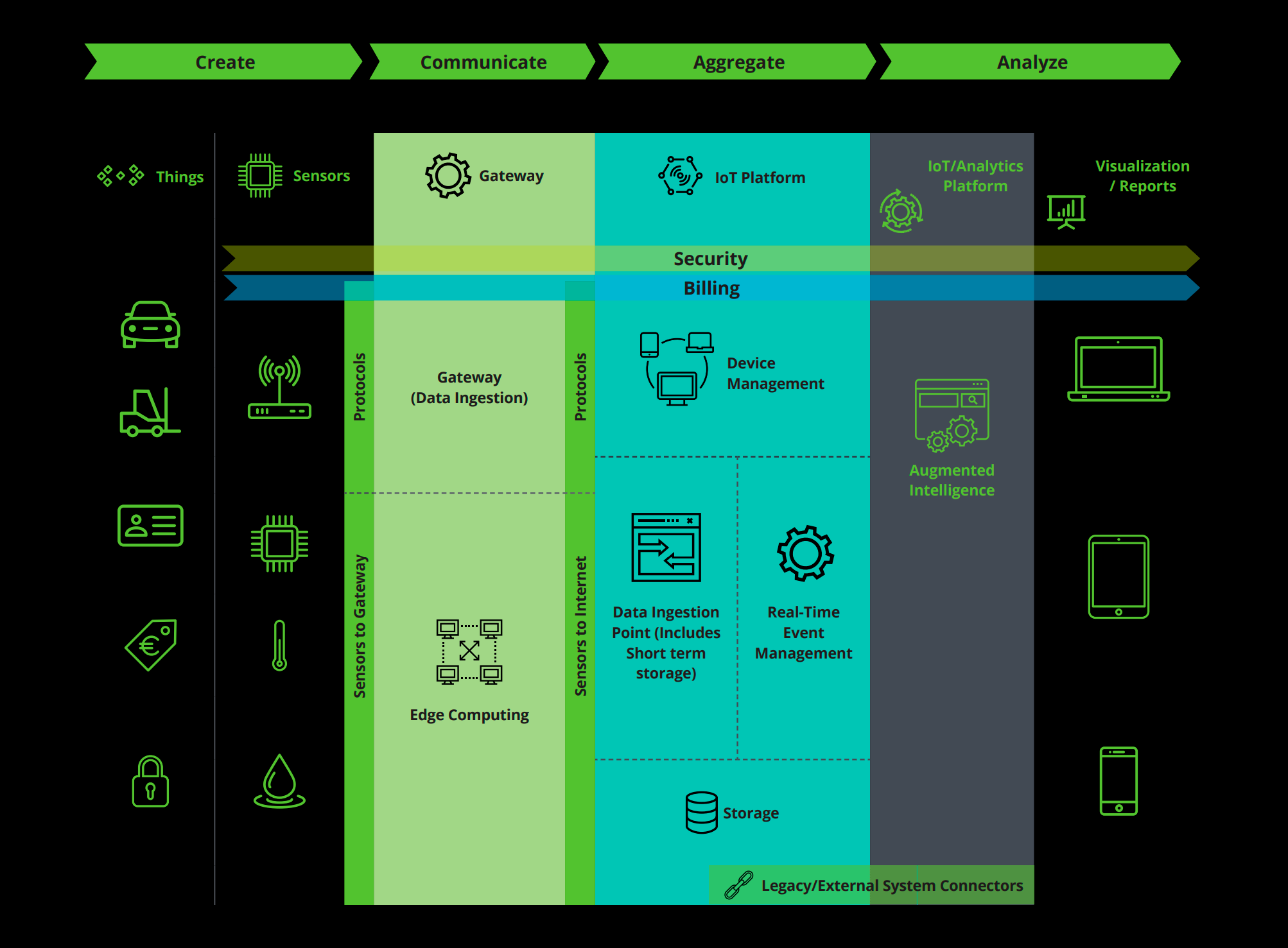

An example of an IoT architecture for transportation (source: Deloitte)

An example of an IoT architecture for transportation (source: Deloitte)Issue #3. Security

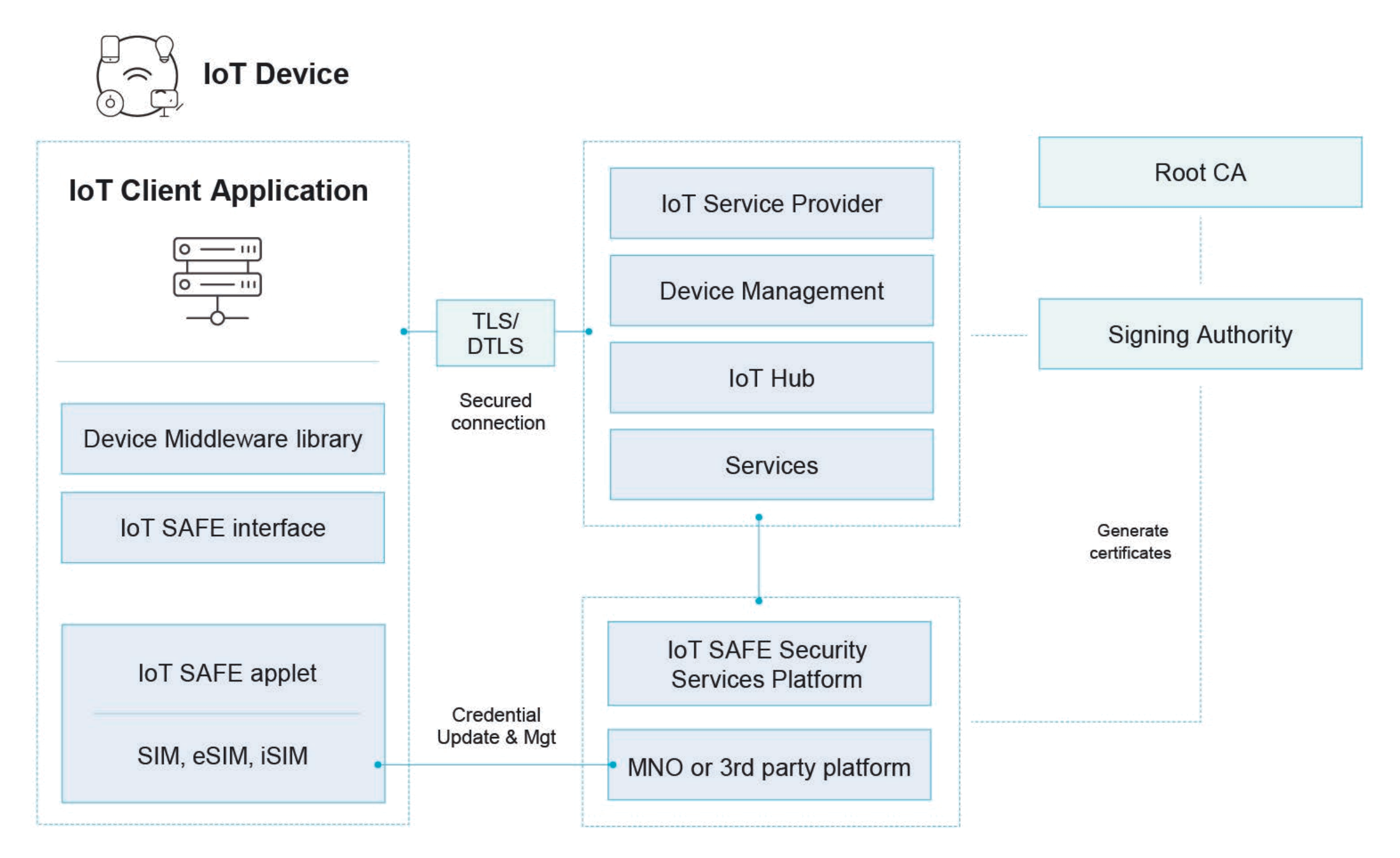

Wide networks of interconnected IoT devices can suffer from multiple points of vulnerability. This makes cybersecurity a top-tier parameter when building or choosing an IoT solution, as pointed out by McKinsey. Among the features to protect your IoT platform from data breaches and hacks, Amazon mentioned access management, device authentication and authorization, data encryption, event management, etc.

Further protection can be achieved by relying on cryptographic protocols, including Transport Layer Security (TLS), or technologies such as blockchain. The latter was mentioned by Deloitte as one of the innovations set to enhance the role of IoT in logistics. Specifically, blockchain-based architectures and algorithms make sure that information collected through IoT devices is not altered after being stored. In practical terms, this prevents carriers from modifying any relevant documentation, such as waybills.

An example of an IoT architecture with TLS (source: GSMA)

An example of an IoT architecture with TLS (source: GSMA)Issue #4. Battery durability

Batteries run out, and those powering IoT sensors are no exception. The European Commission reported that most devices have a 10-years operational life, while their batteries can last less than 2 years. Research in this field is still ongoing, focusing on the creation of batteries that can recharge themselves through heat, vibration, or lights (for example, via microsolar cells).

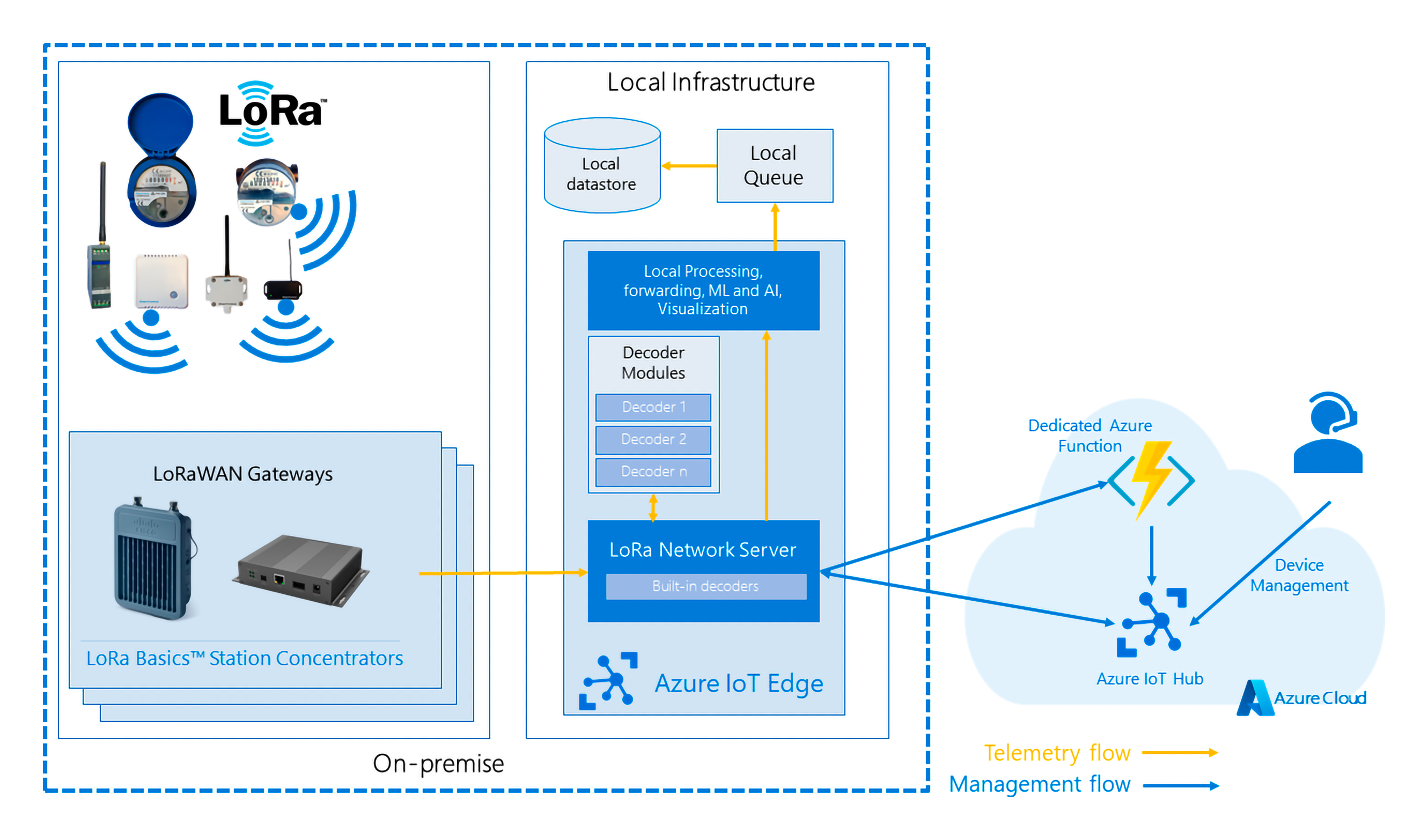

In the meantime, what transport providers can do is minimize consumption. Low-power protocols and technologies, such as LoRaWAN, can help in this regard. As for short-range connectivity, Inmarsat’s report mentioned Bluetooth Low Energy (BLE). Due to its intrinsic nature, however, BLE can be used just for specific logistics operations rather than long-range monitoring.

Using LoRaWAN gateways in the IoT architecture (source: Microsoft)

Using LoRaWAN gateways in the IoT architecture (source: Microsoft)Issue #5. Load spikes

Holidays and rush hours can put a strain on logistics, as much as on IoT systems used in this industry, due to the consequent spikes in network traffic. A first solution to address this issue is proper network utilization via bandwidth-efficient and lightweight protocols, such as MQTT. In this regard, a test by HiveMQ revealed that sending 100 messages via HTTP required 554,600 bytes, while the same operation with MQTT took only 44,748 bytes.

Another option suggested by HiveMQ is to build a masterless cluster architecture. Basically, networks of cluster nodes (i.e., processing or storage units) without shared resources serve thousands of IoT devices. Depending on the network load, the amount of nodes can be scaled up or down. The devices connected to a certain node can simply switch to another one and resume the current session.

Issue #6. Device maintenance

An IoT sensor can monitor the status of assets and goods. But who monitors the sensor itself? In addition, how to upgrade software on the edge (e.g., install security patches)? Well, these tasks can be challenging, both for the incredible amount of devices involved and for their geographic distribution across vast logistics ecosystems.

To ensure remote, ongoing supervision over each sensor, device management software may help (such as this one by Amazon). This can enable to:

- update firmware on devices remotely

- detect anomalies

- reboot sensors

- configure automatic alerts, etc.

These are only the major technical challenges. Other issues, such as the lack of expertise or limited budgets are also specified by the companies.

Optimized fuel costs and ROI

The IoT has proven extremely valuable for transportation and fleet management. A report by Verizon published in November 2022 discovered that GPS fleet tracking helped respondents to decrease fuel costs by 9% on average. GPS adoption also led to a 17% reduction in expenses associated with vehicle accidents and to a 12% decrease in labor costs. On top of this, 31% of companies reported a positive ROI within 6 months of adopting fleet tracking. As for asset monitoring implementations, 55% saw a positive ROI in less than a year.

On the other hand, the Internet of Things creates new risks and points of vulnerability affecting other supply chain systems. However, a focus on cybersecurity, proper integration, and reliable connectivity can minimize such issues, making sure that the IoT is an asset and not a problem.

Further reading

- Scaling Industrial IoT in Manufacturing: Challenges and Guidelines

- A Close Look at Everledger—How Blockchain Secures Luxury Goods

- Top 7 Challenges of Product Traceability in Manufacturing Supply Chain

Subscribe to new posts

Contact us and get a quote within 24 hours